Pallets conveying line | Pioneers in Conveyor System Design and Automated Solutions

If you are looking for a pallet conveyor technology that can handle various specifications, then Chain We's automated conveyor equipment is your best choice. Whether it is European, DIN industrial and mesh box pallets, our conveyor equipment can easily adapt. In addition, our conveyor equipment can also transport pallets weighing up to 1500 kilograms and allow the transport of materials up to 1.6 meters wide. Our automated conveyor equipment can also eliminate the return of empty pallets, improve your efficiency and save costs. Chain We's automated conveyor equipment is your best partner for logistics solutions. Chain We is Taiwan comprehensive Storage and Retrieval Conveying System for Pallets manufacturer since 1988. With over 30 years of diversified experience, we specialize in providing customized solutions through our comprehensive one-stop automation service, covering planning, design, manufacturing, installation, and after-sales support. Our expertise extends across a wide range of industries, including semiconductor, electronics, panel manufacturing, logistics centers, automatic warehouse peripheral transmission systems, medical facilities, food processing, paper production, automotive, and various other sectors.

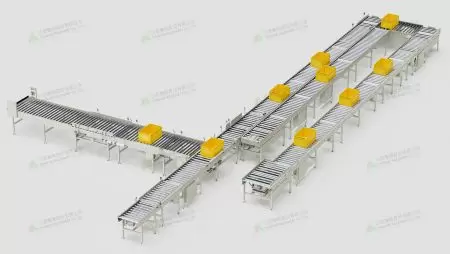

Pallets conveying line

If you are looking for a pallet conveyor technology that can handle various specifications, then Chain We's automated conveyor equipment is your best choice. Whether it is European, DIN industrial and mesh box pallets, our conveyor equipment can easily adapt. In addition, our conveyor equipment can also transport pallets weighing up to 1500 kilograms and allow the transport of materials up to 1.6 meters wide. Our automated conveyor equipment can also eliminate the return of empty pallets, improve your efficiency and save costs. Chain We's automated conveyor equipment is your best partner for logistics solutions.

Applications

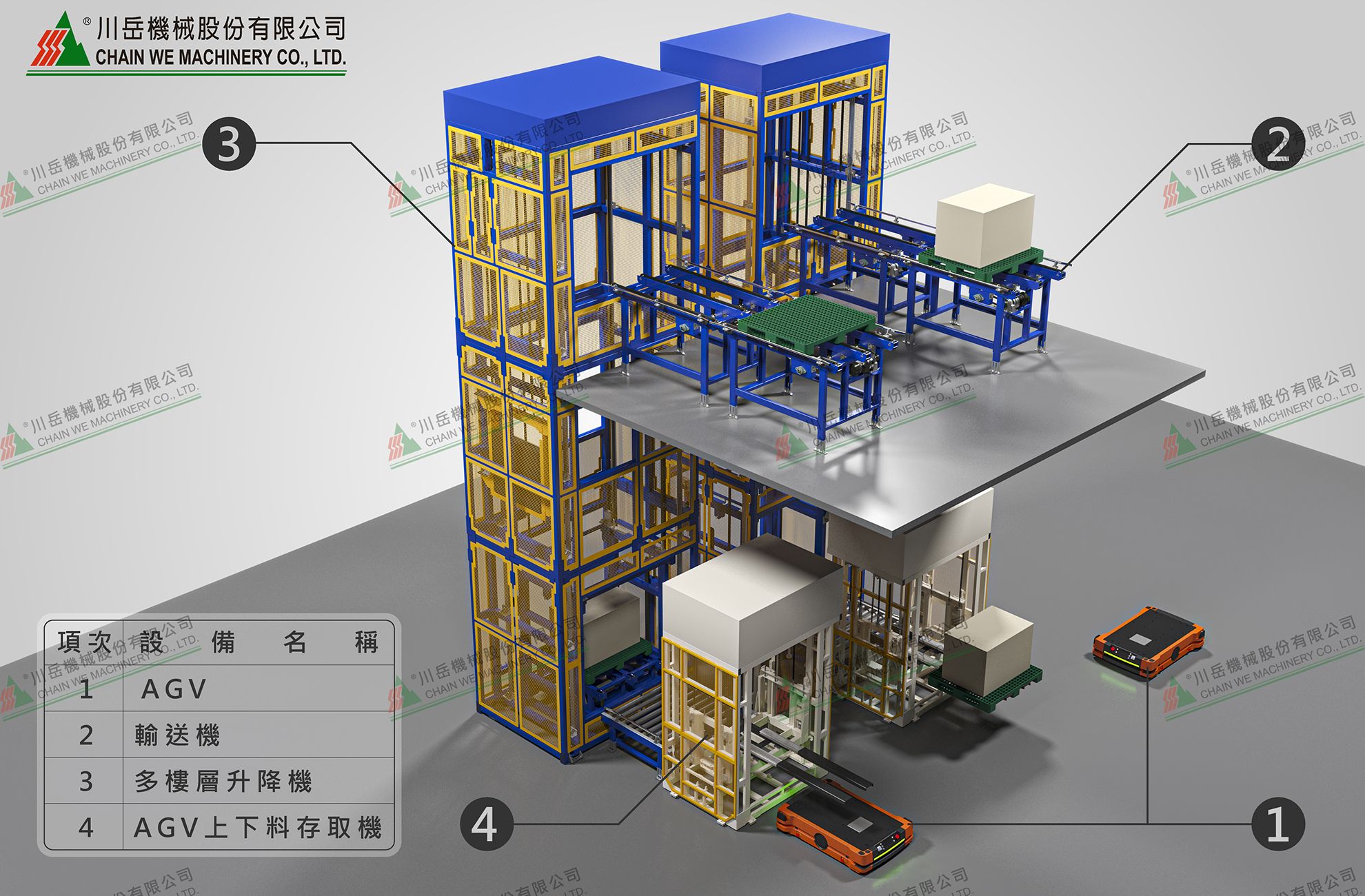

Pallet conveying system is utilized in conveying, temporary storage, warehousing, dismantling / palletizing, tape-laying, film wrapping, import/export, etc., and can be customized to transport pallets of various sizes and materials, improving production efficiency with diversified functional mechanisms.

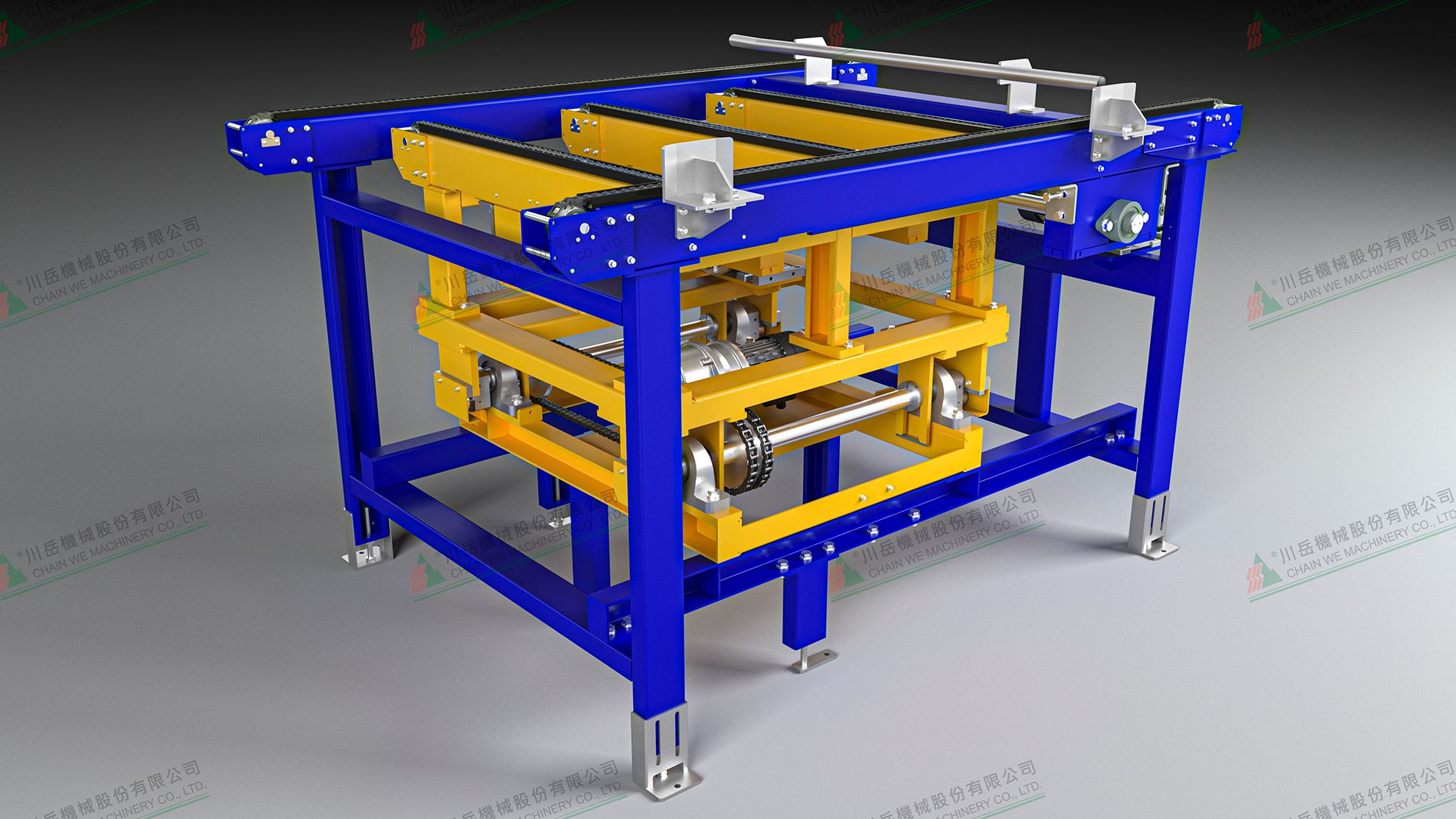

Transfer conveyor are a type of automated conveyor equipment that can handle heavy applications such as pallets, motors, drums or manufactured components up to 1 ton. Chain transfers can also divert pallets 90 degrees to different directions, such as parallel or perpendicular conveyor lines or workstations. This allows you to optimize your space and workflow. You can customize your chain transfers with two or three chains depending on your load size and weight. Chain transfers are your best solution for heavy load handling and pallet diversion.

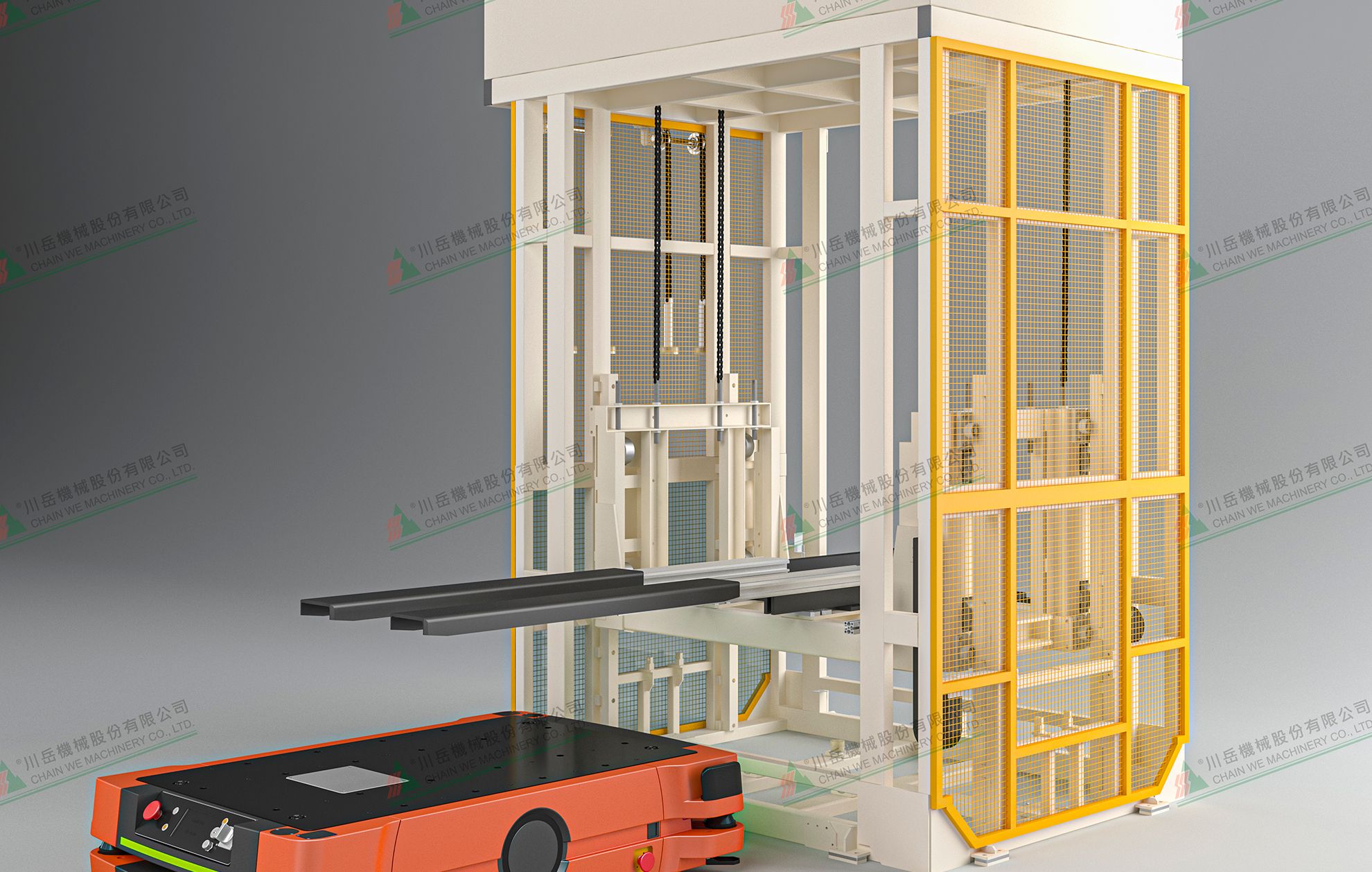

Chain We's AGV system is a type of automated conveyor equipment that can smoothly transfer loads to and from conveyors without human intervention. Our AGVs can also combine with a short-stroke elevator to form a docking system that provides fluid and accurate positioning of the load on the conveyor. This can improve your productivity and reduce your labor costs. In addition, our AGVs can interface with automated storage and retrieval systems (AS/RS) as well as other conveyors. Our conveyor deck AGVs are your best solution for pallet and rack handling and transfer.

Chain We Machinery's Cargo Lift is a type of automated conveyor equipment that can lift and transport heavy duty materials such as machines, vehicles, pallets or forklifts between different floors. Our Cargo elevator is suitable for various applications such as garages, warehouses, factory plants, industrial spaces, racking systems and more. The industrial freight elevator has a wide range of capacity from 50 kgs to 2 ton and table size that can meet your specific needs. Our Cargo Lift can also reach up to 6 stops and 3 ~ 20 meters in height.

Features

- Reduce production downtime.

- Achieve comprehensive visibility for inventory scheduling across warehouses.

- Optimize labor efficiency, equipment, and cost.

- Improve warehouse space utilization and significantly reduce physical inventory execution costs.

Specification

- Pallets Conveying Line can be designed according to the size and layout of the plant, such as, plant area 500~5000 square meters.

- The Palletizing System can handle 5~30 pallets per hour.

- The payload of Cargo Lift can be from 30~1000 Kgs.

- Video

- Related Products

Conveyor line for logistics box

Our automated carton & boxes conveyor system & equipment covers a range of processes, including...

DetailsPalletizer system

Palletizer systems are able to integrate with Robotic Arm for dismantling / palletizing operations,...

DetailsLift for AGV Docking

Lift for AGV Docking can enable automated material handling between different floor levels...

DetailsVertical reciprocating elevator

Chain We Machinery's Vertical Reciprocating Elevator: A Space-Saving and Cost-Effective Solution...

DetailsVertical reciprocating conveyor

Chain We's Vertical reciprocating conveyor for Clean Room: A Dust-Free and Sterile Solution...

Details

Pallets conveying line | Experts in Advanced Conveyor Technologies and Automation

Chain We Machinery, established in 1988 and headquartered in Taiwan, is a leading provider of customized conveyor systems and automation solutions. With over 25 years of experience, we specialize in the planning, design, manufacturing, installation, and support of a wide range of products, including Pallets conveying line, conveyor systems, assembly line conveyors, ASRS conveying equipment, robotic palletizing machines, and pallet dispensers.

With over 30 years of diversified experience, we specialize in providing customized solutions through our comprehensive one-stop automation service, covering planning, design, manufacturing, installation, and after-sales support. Our expertise extends across a wide range of industries, including semiconductor, electronics, panel manufacturing, logistics centers, automatic warehouse peripheral transmission systems, medical facilities, food processing, paper production, automotive, and various other sectors.

Chain We has been offering our customers innovative solutions in conveyor systems and automation since 1988. With both advanced technology and 25 years experience, Chain We always makes sure to meet each customer's demand.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.