Conveyor line for logistics box | Pioneers in Conveyor System Design and Automated Solutions

Our automated carton & boxes conveyor system & equipment covers a range of processes, including conveying, handling, packing, diverting, opening / sealing, temporary storage, warehousing, dismantling / palletizing, tape-laying, film wrapping, and import / export. Our Carton & Boxes Conveyor System is designed based on the size and needs of the plant, so it can be large or small, for example, 12,500 square meters.

This highly customizable system can be adapted for use with various mechanisms to suit individual requirements. Our versatile system is suitable for a wide range of industries, including Wholesale and Retail, Transportation and Warehousing, Logistics, and various types of manufacturing, such as food, hardware, and OEM. Chain We is Taiwan comprehensive Cardboard boxes conveyor, carton conveyor manufacturer since 1988. With over 30 years of diversified experience, we specialize in providing customized solutions through our comprehensive one-stop automation service, covering planning, design, manufacturing, installation, and after-sales support. Our expertise extends across a wide range of industries, including semiconductor, electronics, panel manufacturing, logistics centers, automatic warehouse peripheral transmission systems, medical facilities, food processing, paper production, automotive, and various other sectors.

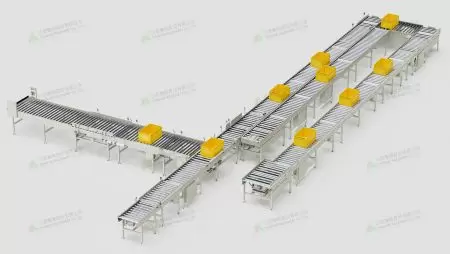

Conveyor line for logistics box

Cardboard boxes conveyor, carton conveyor

Our automated carton & boxes conveyor system & equipment covers a range of processes, including conveying, handling, packing, diverting, opening / sealing, temporary storage, warehousing, dismantling / palletizing, tape-laying, film wrapping, and import / export. Our Carton & Boxes Conveyor System is designed based on the size and needs of the plant, so it can be large or small, for example, 12,500 square meters.

This highly customizable system can be adapted for use with various mechanisms to suit individual requirements. Our versatile system is suitable for a wide range of industries, including Wholesale and Retail, Transportation and Warehousing, Logistics, and various types of manufacturing, such as food, hardware, and OEM.

Applications

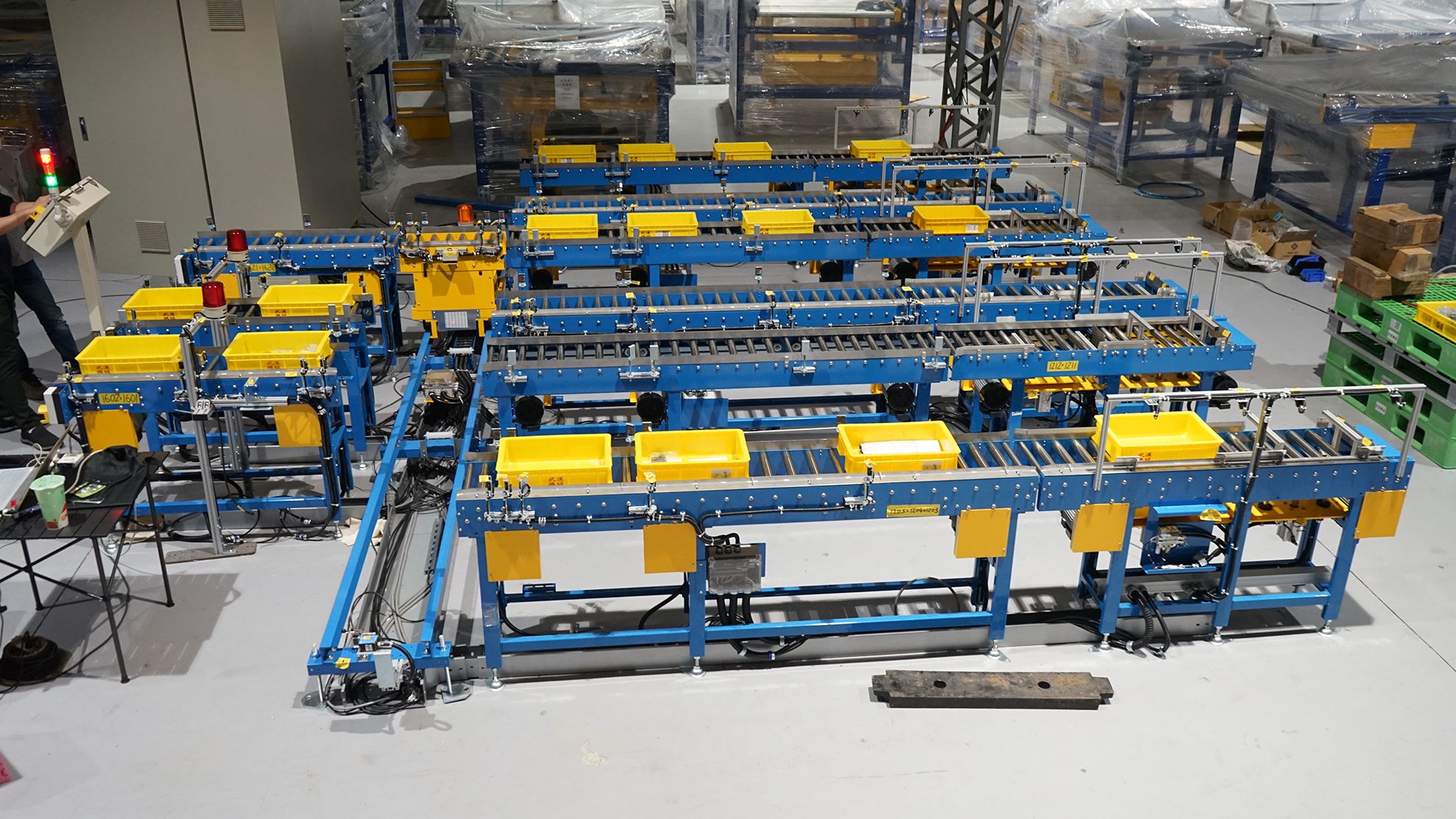

The double layer conveying line for boxes enables items to be transported back and forth in the same space, thereby saving valuable horizontal area. This feature makes it particularly advantageous for battery production.

Our aim is to ensure that your system runs smoothly and efficiently, giving you complete peace of mind.

The RGV Conveyor System for Boxes provides fast and efficient conveying and retrieval functions, making it ideal for quick sorting operations. We have a skilled team of professionals who can provide customers with comprehensive technical support and solutions.

The Sorting Conveying System accurately diverts and conveys packages of different sizes, especially in logistics industries that require barcode scanning and sorting processes. Our convey system can seamlessly integrate with other automation solutions to provide a comprehensive solution for your entire production line. With our conveyor and sort automation, you can efficiently process large quantities of inventory.

The Multi-floor Operation System for Boxes allows the conveying system to operate on different floors.

We continuously optimize and improve automated conveyor system to enhance system stability, reliability, and efficiency, and to meet the evolving needs of our customers.

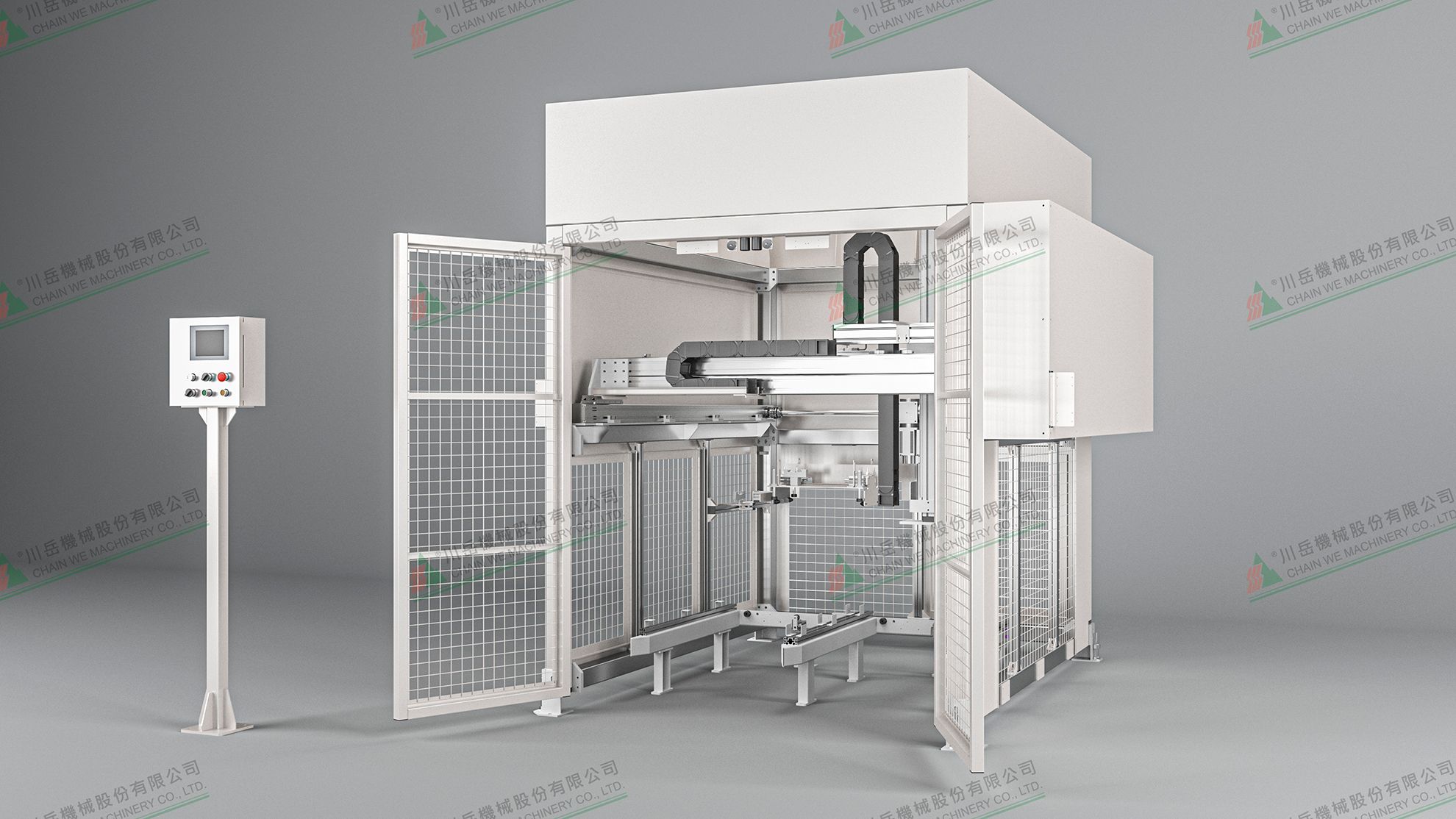

The XYZ Table can automatically stack and temporarily store material and carton boxes using its adjustable 3-axis feature. With the proper mechanism, it can achieve simple automatic storage and retrieval functions.

With our efficient production management system and extensive manufacturing experience, we can guarantee delivery stability and timeliness. We offer customized production to provide tailored solutions that meet the specific needs of our clients.

Features

- Reduce production downtime.

- Achieve comprehensive visibility for inventory scheduling across warehouses.

- Optimize labor efficiency, equipment, and cost.

- Improve warehouse space utilization and significantly reduce physical inventory execution costs.

Specification

- Conveyor line for logistics box can be designed according to the size and layout of the plant, such as, plant area 500~5000 square meters.

- The RGV Conveyor System can handle 60~100 boxes per hour.

- The length of Double Layer Conveying Line can be from 150~1500m.

- The payload of vertical conveyor elevator can be from 30~1000 Kgs.

- Video

- Related Products

Pallets conveying line

If you are looking for a pallet conveyor technology that can handle various specifications,...

DetailsPalletizer system

Palletizer systems are able to integrate with Robotic Arm for dismantling / palletizing operations,...

DetailsRoller Conveyor Integration

Chain We Machinery: The Expert in Roller Conveyor Integration and Automation Roller conveyors...

Details

Conveyor line for logistics box | Experts in Advanced Conveyor Technologies and Automation

Chain We Machinery, established in 1988 and headquartered in Taiwan, is a leading provider of customized conveyor systems and automation solutions. With over 25 years of experience, we specialize in the planning, design, manufacturing, installation, and support of a wide range of products, including Conveyor line for logistics box, conveyor systems, assembly line conveyors, ASRS conveying equipment, robotic palletizing machines, and pallet dispensers.

With over 30 years of diversified experience, we specialize in providing customized solutions through our comprehensive one-stop automation service, covering planning, design, manufacturing, installation, and after-sales support. Our expertise extends across a wide range of industries, including semiconductor, electronics, panel manufacturing, logistics centers, automatic warehouse peripheral transmission systems, medical facilities, food processing, paper production, automotive, and various other sectors.

Chain We has been offering our customers innovative solutions in conveyor systems and automation since 1988. With both advanced technology and 25 years experience, Chain We always makes sure to meet each customer's demand.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.