Rail guided vehicle system

Rail guided vehicle (RGV) system is a type of automated material handling system that uses RGVs to transport goods along fixed rails. RGVs are suitable for docking with a forklift, which can transfer goods from the RGVs to the designated location. RGVs can also be applied to the loading and unloading of automatic warehouse systems, where they can transport pallets, boxes, or other items between different storage racks or stations. RGV system has many advantages over other types of automated material handling systems, such as higher speed and accuracy, lower maintenance and operation costs, higher safety and reliability, and higher scalability and flexibility.

RGV system can support multi-production line transportation, which can increase the production capacity and flexibility of the factory. RGV system is also suitable for fastener and stamping small parts industry, where it can handle the loading and unloading of small and delicate parts efficiently and accurately. The unloading machine uses hydraulic pressure to dump the material safely and reliably, preventing spillage or damage. RGV system is widely used in various industries, such as manufacturing, logistics, and e-commerce. With the development of technology and innovation, RGV system will continue to play an important role in the automation and digitalization of various industries.

- Video

- Related Products

Rail guided vehicle for warehouse

Rail Guided Vehicles (RGV) Systems by Chain We RGV Systems are automated vehicles that run on rails...

DetailsRGV with roller conveyor

RGV with roller conveyor is a smart and effective way to integrate your production line. RGV with...

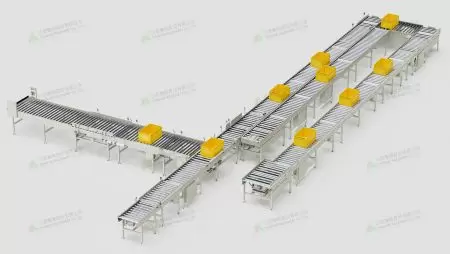

DetailsConveyor line for logistics box

Our automated carton & boxes conveyor system & equipment covers a range of processes, including...

Details

How Can RGV Systems Reduce Operational Costs While Increasing Warehouse Throughput?

Our RGV systems deliver lower maintenance and operation costs compared to traditional material handling equipment while providing higher speed and accuracy for automated warehouse operations. With seamless ASRS integration and intelligent forklift docking, you can transport pallets and boxes between multiple storage racks efficiently, maximizing throughput and minimizing labor costs. Contact our automation specialists to design a customized RGV solution that scales with your logistics center's growth.

Leveraging over 30 years of expertise in customized conveying systems, Chain We Machinery delivers RGV solutions that offer superior advantages over conventional material handling systems, including reduced maintenance and operation costs, enhanced scalability, and exceptional flexibility. Our rail guided vehicle systems support multi-production line transportation, significantly increasing production capacity and operational efficiency across manufacturing, logistics, and e-commerce facilities. Manufactured in our state-of-the-art 14,500 square meter facility equipped with Industry 4.0 technology, each RGV system is engineered to meet the evolving demands of automation and digitalization. Contact us today to discover how our comprehensive one-stop automation service can transform your material handling operations from initial planning through installation and ongoing maintenance support.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.