Robotic palletizing systems | Chain We

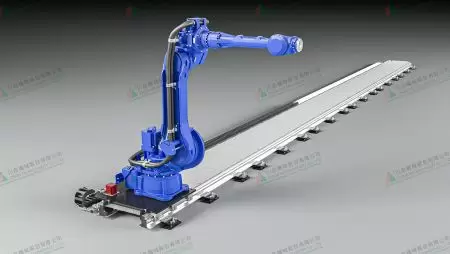

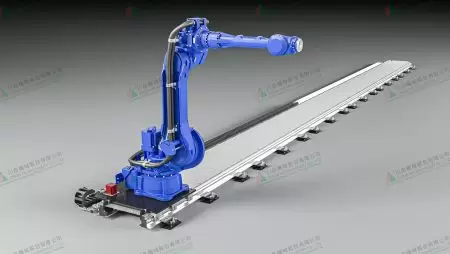

Automated Robotic Palletizer System by Chain We Machinery can compatible with the seventh-axis linear module to increase the operation range. This means that the robotic arm can move along a horizontal track to reach multiple palletizing stations or different product lines. Explore conveyor products across Chain We categories to match your line or warehouse needs. Review product pages for functions, applications, and integration notes. Contact Chain We for configuration guidance and quotations.

Robotic palletizing systems

Automated Robotic Palletizer System by Chain We Machinery can compatible with the seventh-axis linear module to increase the operation range. This means that the robotic arm can move along a horizontal track to reach multiple palletizing stations or different product lines.

Benefits

Increase capacity by integrating different automatic processes. This means that the robotic palletizer can perform multiple functions such as depalletizing, palletizing, wrapping, labeling, etc. in one system.

Reduce labor costs and risks. This means that the robotic palletizing systems can replace manual labor and reduce the risk of injuries, errors, and fatigue.

Enhance product quality and customer satisfaction. This means that the robotic palletizer can ensure consistent and precise stacking of boxes and pallets, reducing product damage and waste.

If you are looking for a smart solution for your boxes and pallets, a robotic palletizer is the right choice for you. Contact us to find out more about our robotic palletizer products and services.

Specification

- Increase system reliability and uptime, enhance overall throughput.

- Improve ergonomic conditions, reduce operating costs, handle heavy lifting and repetitive movements.

- Seamless integration, flexible and scalable, in sync with business growth.

- Robotic Palletizing Systems can interface with upstream and downstream equipment for fully automated operations.

- Can handle various products including cases, totes, bags, trays...etc.

- Video

- Related Products

Seventh axis linear module

Seventh axis linear module of the Robotic Arm endows the original six-axis Robot with the seventh-axis...

DetailsConveyor and robotic integrated solution

Robotic and Conveyor Integration can boost your productivity and save costs. Robotic and conveyor...

Details7th Axis robot transfer unit

Chain We Machinery's 7th Axis Robot Transfer Unit is a rack and pinion drive system that can easily...

DetailsHeavy duty pallet dispenser

A heavy-duty pallet dispenser is a device that provides empty pallets to an automated material...

Details

Robotic palletizing systems | Chain We

Need higher throughput and smoother material flow? Chain We builds Robotic palletizing systems to match your load, line speed, and layout—supporting stable transfer, controlled accumulation, and easier integration with sensors and PLC control.

Since 1988, Chain We in Taiwan has delivered customized conveyor systems and automation solutions, including assembly line conveyors, ASRS conveying equipment, robotic palletizing integration, pallet dispensers, and project-based system engineering.

Typical applications include semiconductor and electronics lines, panel manufacturing, logistics and automated warehouses, plus medical, food, paper, and automotive operations—helping teams reduce manual handling and keep production running consistently.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.